Presenter Name: Paul Walker

Additional Presenters:

Hyunook Kim (kabin105@gmail.com)

Description

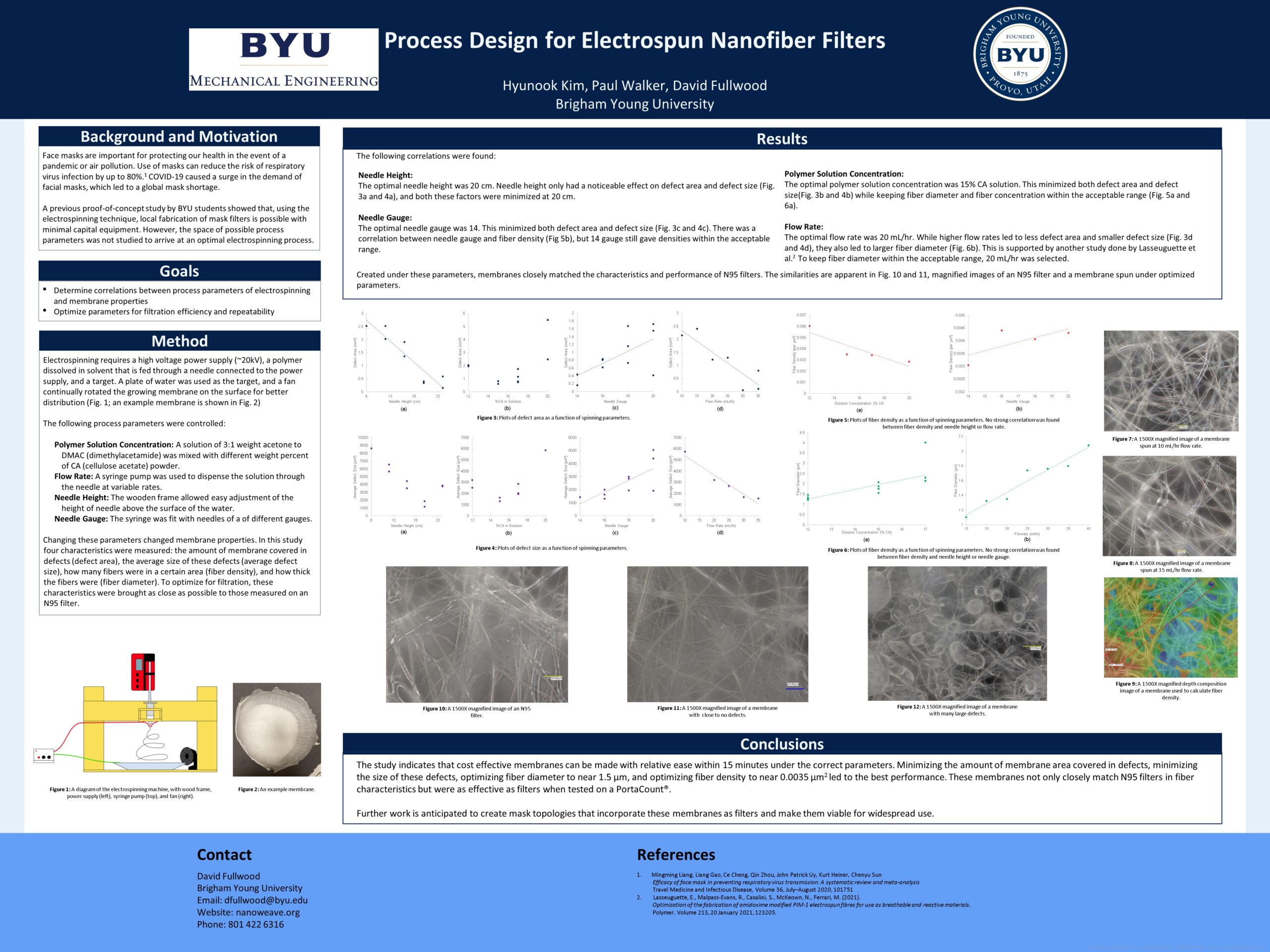

Mask filters are important for the protection of the community in the event of a pandemic or to protect people from pollutants endemic to our major cities. N95 has been the standard for an effective filter in the medical industry, but such masks were not readily available as the COVID 19 pandemic unfolded. Our goal is to develop a filter production method that could be fabricated by a cottage industry, if necessary, using a method designed to be both accessible and inexpensive. Electrospinning is the process of using an electronic force to pull polymers out of solution and make nanofibers. Layering these fibers on top of each other creates membranes that can be used as filters in masks. To develop a robust process based upon this method, we explored the effects of different environmental and process variables on the resultant membrane. Specifically, we study how process parameters can be changed to optimize the membrane's performance as a filter and thereby create a reliable, replicable process for creating membranes. This study focused on a range of influential process parameters, including the distance of the electrospinning needle from the membrane surface, the needle gauge, the flow rate, and the mass concentration of the solution. The influence of these parameters on the resultant fiber diameter and effective filtration of the membrane was quantified. The results of the study lead to the design of a robust, effective and accessible process for spinning N95-compliant membranes that may benefit communities in all quarters of the world.

University / Institution: Brigham Young University

Type: Poster

Format: In Person

Presentation #D93

SESSION D (3:30-5:00PM)

Area of Research: Engineering

Email: pkwalker19@gmail.com

Faculty Mentor: David Fullwood