Presenter Name: Jackson Rose

Additional Presenters:

PJ Martin

Description

Advanced Alkaline Amine Fuel Cell Development

Jackson Rose, Perry Martin, Kevin Shurtleff*

Utah Valley University, Chemistry Department

*corresponding author: kshurtleff@uvu.edu, 801-360-9799 Abstract

In the modern era, perhaps the most pressing issue is that of power generation. It is important that a source which is inexpensive, reliable, efficient, sustainable, and carbon free be developed. One such effort has been to develop the hydrogen fuel cell. Fuel cells meet many of the requirements listed above save one, current designs are too expensive. The catalysts used in most modern hydrogen fuel cells are often platinum group metals, which significantly increases the cost of manufacturing. The resulting high price has proved a significant barrier to adoption.

Alkaline fuel cells are comparatively cheap as the catalysts are relatively inexpensive, but they suffer from some reliability issues. One problem with alkaline fuel cells is the formation of carbonates, which are often produced when carbon dioxide reacts with the potassium hydroxide electrolyte. During operation, carbonates tend to build up on the catalytic sites rendering the fuel cell completely inoperable. However, the chemistry can be manipulated to eliminate this failure. The potassium hydroxide electrolyte in an alkaline fuel cell can be replaced with an organic amine. Carbonates are soluble in many amines and thus will not precipitate out of solution. This will prevent carbonates from building-up on the catalytic site and may and even clean these sites.

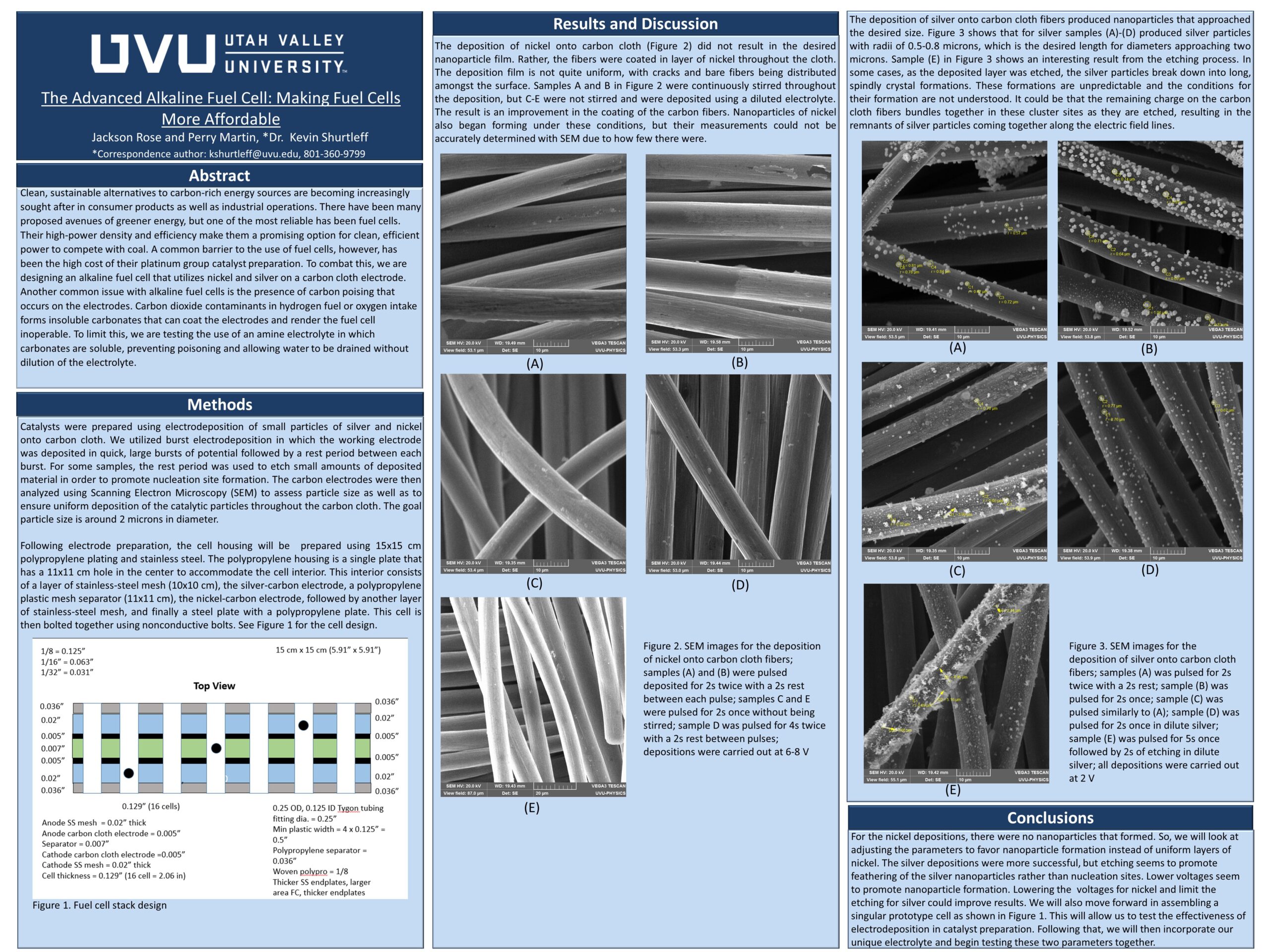

At Utah Valley University, strategies for extremely low-cost fuel cell production are being designed and tested. Currently, nickel and silver nanoparticle catalysts are being electrodeposited onto carbon cloth samples, which are then examined via S.E.M. The purpose of this is to establish what size of electrodeposited particles will afford the maximum catalytic activity. Optimizing particle size for the hydrogen oxidation reaction will help to improve efficiency and effectiveness of the fuel cell, which will reduce costs. Smaller model samples are to be built to test both the amine as well as the different catalyst samples. Once an optimal particle size and amine have been identified, scaling the process is next. The goal for this identification is by the end of the year this year. Early into next year, the scaling will begin. A full-scale alkaline amine fuel cell system will be built. It will be tested as a twelve volt system for current density, lifetime and total costs for comparison to other fuel cell systems.

Utah Valley University, Chemistry Department

*corresponding author: kshurtleff@uvu.edu, 801-360-9799 Abstract

In the modern era, perhaps the most pressing issue is that of power generation. It is important that a source which is inexpensive, reliable, efficient, sustainable, and carbon free be developed. One such effort has been to develop the hydrogen fuel cell. Fuel cells meet many of the requirements listed above save one, current designs are too expensive. The catalysts used in most modern hydrogen fuel cells are often platinum group metals, which significantly increases the cost of manufacturing. The resulting high price has proved a significant barrier to adoption.

Alkaline fuel cells are comparatively cheap as the catalysts are relatively inexpensive, but they suffer from some reliability issues. One problem with alkaline fuel cells is the formation of carbonates, which are often produced when carbon dioxide reacts with the potassium hydroxide electrolyte. During operation, carbonates tend to build up on the catalytic sites rendering the fuel cell completely inoperable. However, the chemistry can be manipulated to eliminate this failure. The potassium hydroxide electrolyte in an alkaline fuel cell can be replaced with an organic amine. Carbonates are soluble in many amines and thus will not precipitate out of solution. This will prevent carbonates from building-up on the catalytic site and may and even clean these sites.

At Utah Valley University, strategies for extremely low-cost fuel cell production are being designed and tested. Currently, nickel and silver nanoparticle catalysts are being electrodeposited onto carbon cloth samples, which are then examined via S.E.M. The purpose of this is to establish what size of electrodeposited particles will afford the maximum catalytic activity. Optimizing particle size for the hydrogen oxidation reaction will help to improve efficiency and effectiveness of the fuel cell, which will reduce costs. Smaller model samples are to be built to test both the amine as well as the different catalyst samples. Once an optimal particle size and amine have been identified, scaling the process is next. The goal for this identification is by the end of the year this year. Early into next year, the scaling will begin. A full-scale alkaline amine fuel cell system will be built. It will be tested as a twelve volt system for current density, lifetime and total costs for comparison to other fuel cell systems.

University / Institution: Utah Valley University

Type: Poster

Format: In Person

Presentation #B79

SESSION B (10:45AM-12:15PM)

Area of Research: Science & Technology

Email: jacksonrose97@gmail.com

Faculty Mentor: Kevin Shurtleff